Edwards Vacuum Solutions for

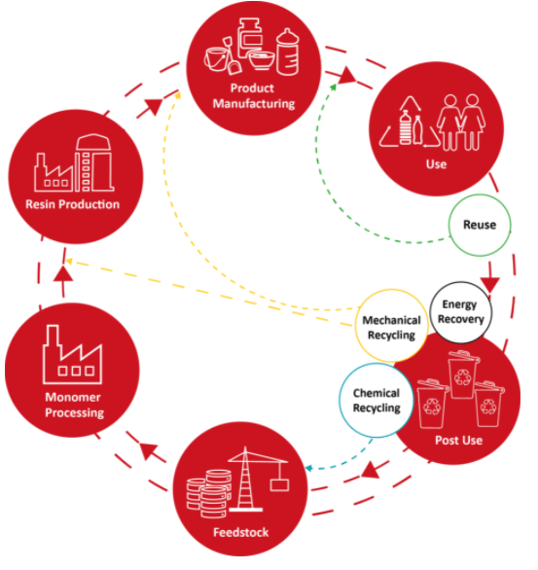

Plastics Circular Economy

Lower your Energy Consumption

Raising cost of power makes it more and more important to use equipment that optimises energy consumption while maintaining throughput. Edwards vacuum solutions use state-of-the-art technology with variable speed drive and efficient motors to make sure your production has the least downtime and a lower utility bill.

Talk to our Experts About

Energy Efficient Manufacturing of Plastics Raw Materials

- Plant-based polymers

- Food grade polymer

- Bio-based polymers

- Extrusion lines for sheet, film and tubes production

- Masterbatches and Compounding

- Extruder degassing

- Solid state recycling

- Chemical Recycling

- Open and Closed - loop recycling

Limited Number of Expert Consultations Available. Please Book Now!

Please select your desired day from the buttons below and request a time to meet.

Frank Achenbach

Edwards Industrial

Vacuum Sales Expert

Manfred Nagel

Edwards Industrial

Vacuum Sales Expert

Browse Our Vacuum Solutions for Plastics Industry

EXDM Standard System

Extruder Degassing module (EXDM) is available in fully automated, with a junction box or with easy logic manual operation for optimised extrusion degassing of your process. Customise your filtration requirements, now available as standard option.

GXS Dry Screw Pumps

Extruder Degassing module (EXDM) is available in fully automated, with a junction box or with easy logic manual operation for optimised extrusion degassing of your process. Customise your filtration requirements, now available as standard option.

EDS Dry Screw Pumps

EDS, available in air-cooled or water-cooled options deliver faster processing and longer service intervals. With dry vacuum technology is capable of processing of hygroscopic sticky polymers for a trouble-free and cost-effective vacuum solution. abcd

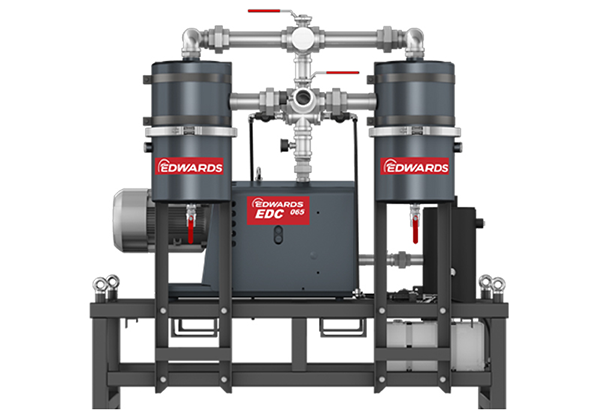

EDC Dry Claw Pumps

EDC claw pumps are simple, robust and efficient with a high contaminant and vapour handling capability. With corrosion resistant stainless steel claws and ease of maintenance, EDC offers lower continuous vacuum with best in class power consumption.

nES Single Stage RVP

Flexible and systemisation friendly, nES single stage rotary vane vacuum pumps are equipped with efficient cooled motors, and an optimised oil retention system for high reliability and minimum maintainence

E2S Two Stage RVP

Modern two staged rotary vane pumps, powerful to boost your production, with fast pump down and high vapour handling capacity for processing hygroscopic polymers.

EOSi Rotary Oil Screw Pump

New EXS series of dry screw pumps have a dependable new gas system with manual gas ballast control for better vapour handling. Inverter driven, for lower power consumption with increased roughing speed

EXS Dry Screw Pumps

New EXS series of dry screw pumps have a dependable new gas system with manual gas ballast control for better vapour handling. Inverter driven, for lower power consumption with increased roughing speed

.jpeg)

.png)

.jpg)